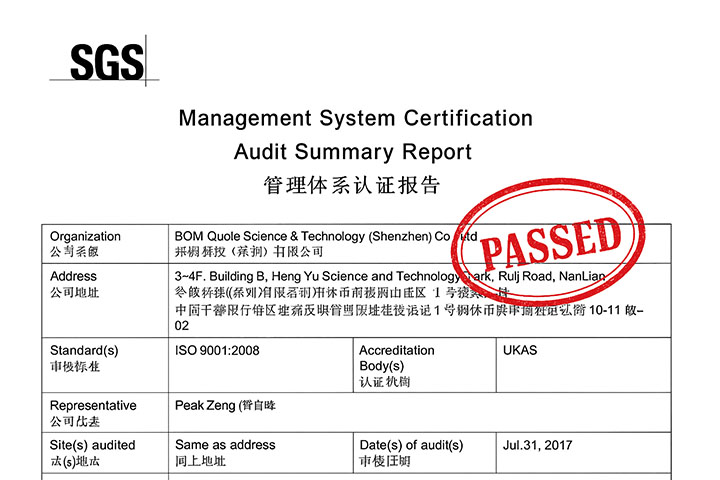

Passed ISO-9001 Audit by SGS

Third-party audited quality management system supporting top-tier retail requirements.

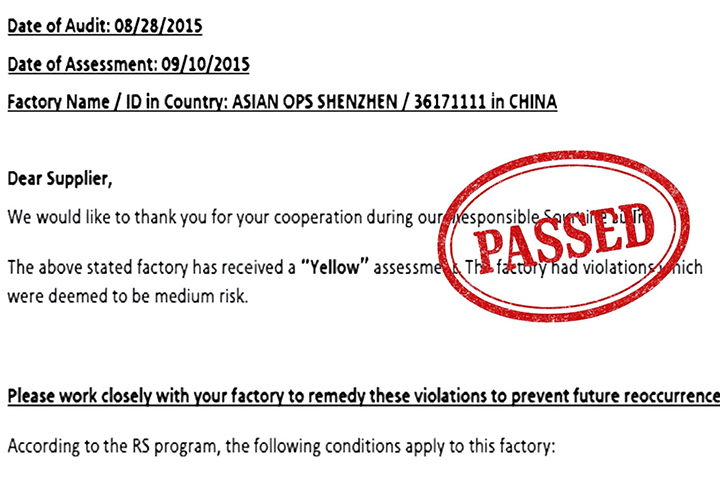

Passed Walmart Sourcing Audit

Meets Walmart responsible sourcing criteria, demonstrating social and ethical compliance.

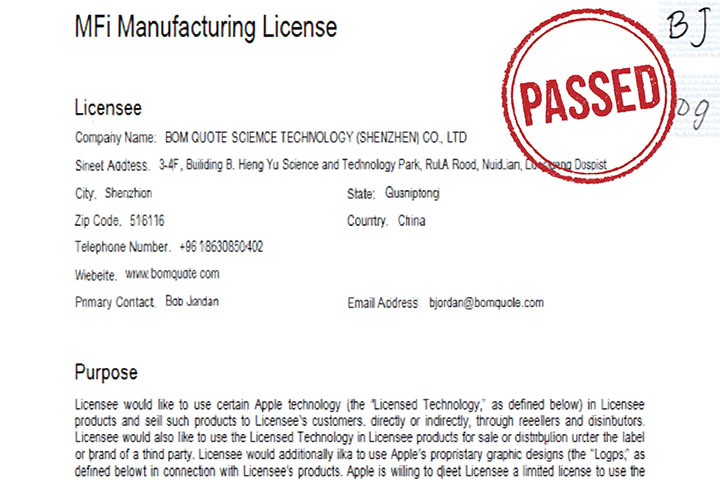

Passed Apple MFi Factory Audit

Apple MFi audit ensures readiness for premium consumer electronics programs.

18,000 sqft Shenzhen Facility

Private factory with SMT, wave solder, QA lab, warehouse, office space and remodeled dorms to attract top talent.

Seasoned Shenzhen Team

Cross-functional experts spanning supply chain, engineering, manufacturing and quality.

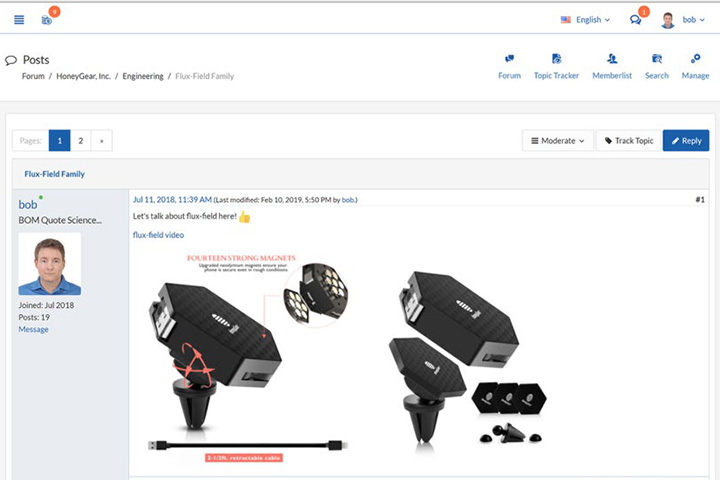

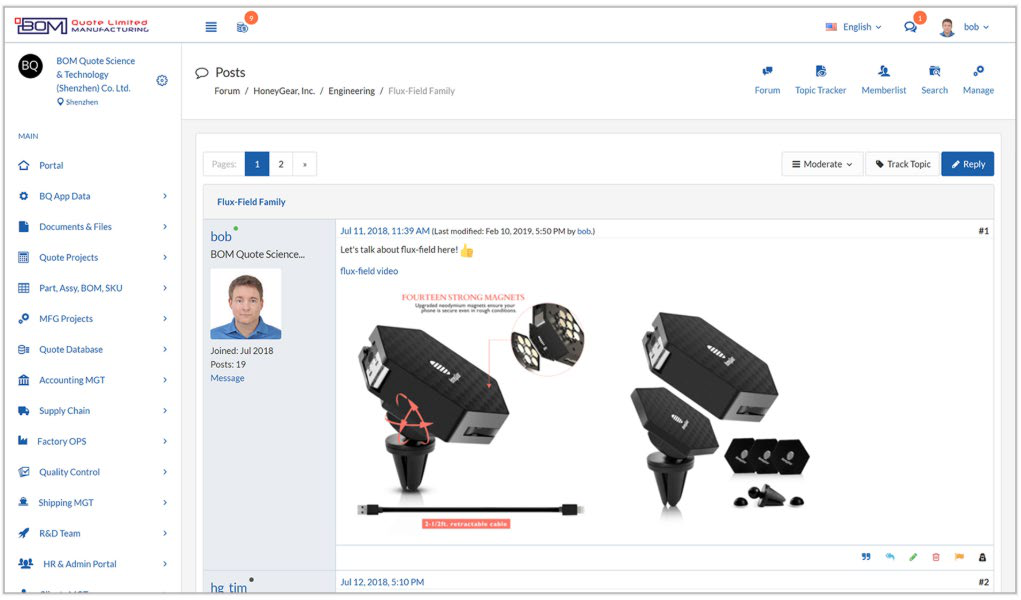

Real-Time Collaboration Platform

App-based portal for BOMs, ECOs, QA, inventory, logistics and accounting-used daily with clients.

Built for Speed, Scale, and Visibility

- 18,000 sqft Shenzhen factory with SMT, wave solder, QA lab, secure warehousing, and remodeled dormitories.

- ISO-9001, Walmart Responsible Sourcing, and Apple MFi audits passed.

- Real-time program collaboration via bomquote.com for BOMs, ECOs, QA, logistics, and accounting.

- American-owned leadership embedded in Shenzhen with a bilingual program team.

Featured Design Programs

Proven electro-mechanical and electronic products launched with our integrated team.

Safety Hard Hat Cooling Platform

Rechargeable fan and mounting system engineered for safety hard hats, delivering internal airflow while remaining low-profile on site.

- Custom PCBA and firmware with 12V fan and LiPo battery pack

- Hard-hat specific mounting hardware with internal cooling shroud

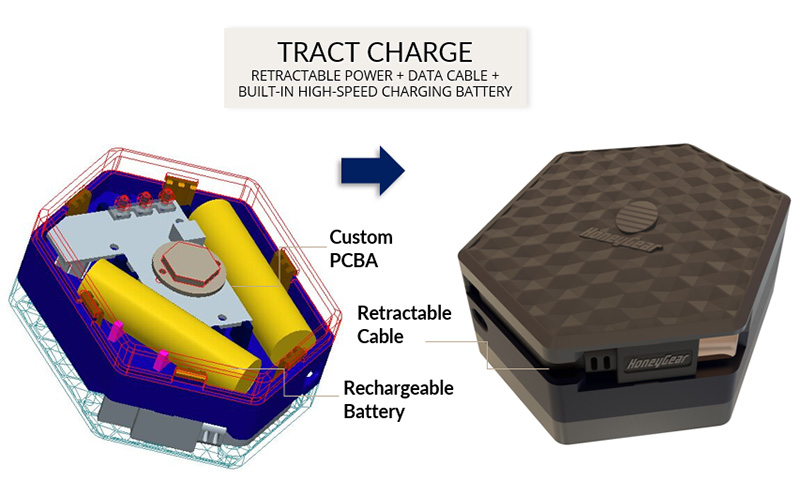

Retractable Cable + Rechargeable Battery

Compact rechargeable battery pack engineered with an integrated three-foot retractable power and data cable for quick charging on the go.

- Custom PCBA and firmware managing dual rechargeable batteries

- Pocket-friendly enclosure that fits easily in bags, pockets, or purses

Water-Activated Sensory Toys

Bath-time sensory toys redesigned from concept through tooling to deliver higher reliability and manufacturability for national retail rollout.

- Eight SKU family produced across ten new injection molds

- Water-activated electronic light cube with re-engineered seals

Design Resources

We use proven frameworks to accelerate DFM, EVT/DVT/PVT planning, and BOM cost-down initiatives.

-

Design-for-Manufacturing Checklist (Electro-Mechanical)

Actionable checklist covering needs identification through tooling, EVT/DVT builds and ramp readiness-mirroring our Design-to-MFG process flow.

- Translate needs into measurable specifications before concept lock

- Capture tooling/LLT requirements early to hit pilot timelines

- Validate readiness with EVT, DVT, and pilot checkpoints

-

EVT/DVT/PVT Roadmap Template

Timeline planner grounded in the six build-and-release phases outlined in our manufacturing phase process, including tooling, pilot and mass production milestones.

- Define acceptance criteria for each build stage

- Document agency/safety testing responsibilities

- Map supply chain readiness alongside engineering actions

-

BOM Cost-Down Playbook

Highlights program management and supply chain levers to reduce landed cost without sacrificing compliance or schedule.

- Align supply-chain planning with production ramp risks

- Use tooling/fixture planning to de-risk quality at scale

- Integrate IQC/OQC/IPQC gates with agency approval cycles

Ready to move from design to launch?

We will review your design files, target volumes, and compliance requirements, then align the right engineering and factory resources.

Book a free DFM review

English

English  简体中文

简体中文