End-to-End Program Leadership

We integrate design reviews, tooling, EVT/DVT/PVT builds, pilot, and mass production within one program team, using a proven phase gate approach.

Start your program briefDesign Phases

From identifying needs through release to manufacturing, each phase prepares the product for a controlled, documented build.

Design Phase Steps

We lead the product design process from concept to manufacturing release.

Needs Identification

Work with stakeholders to surface the true customer needs before locking designs.

Specifications to Meet Needs

Develop quantified objectives that translate end-user needs into engineering targets.

Conceptual Design

Assess feasibility, cost and benefits of competing design concepts prior to embodiment.

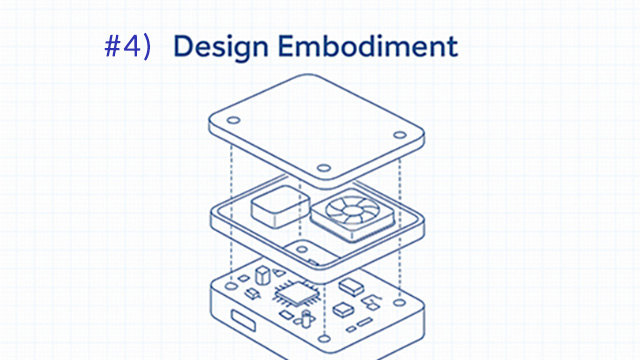

Design Embodiment

Prototype alternative approaches and converge on manufacturable architectures.

Detailed Design

Engineer the detailed plans, drawings and BOM needed to hand off into build phases.

Build, Analysis, & Testing

Build and verify that the design satisfies the specifications.

Release To Manufacturing

Customer needs are met by the design and it is clearly specified.

Manufacturing Phases

Once released, the program transitions into manufacturing readiness, tooling, pilot builds, and scale-up with continuous quality oversight.

Manufacturing Phase Steps

We lead new product introduction to manufacture new designs.

Design-For-MFG Review

Analyze the design and specifications to provide feedback.

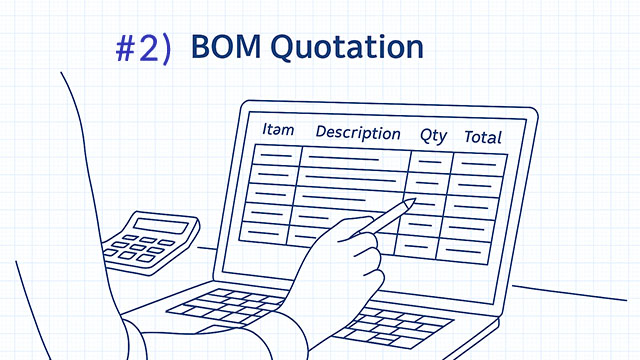

BOM Quotation

Develop line-item quotations covering materials, NRE, labor, overhead and profit.

Quotation Acceptance

Client accepts our manufacturing quotation and places PO with deposit.

Tooling & LLT Phase

Design tooling, build fixtures and procure long-lead components to support pilot builds.

Engineering Build & Test (EVT/DVT/PVT)

Execute engineering builds, lifecycle testing and agency certifications leading into pilot.

Pilot Production

Produce small-batch builds to validate readiness before mass production release.

Mass Production

Release the product to manufacturing after customer approval of pilot builds.

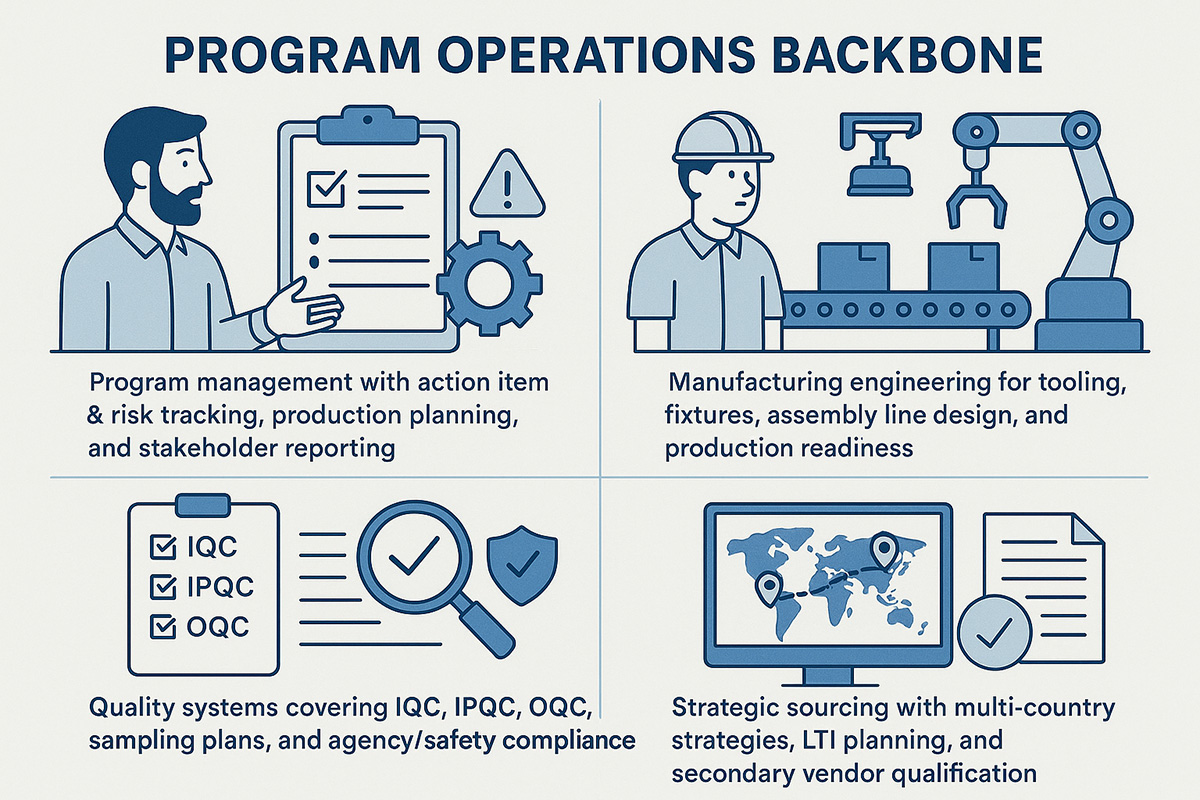

Program Operations Backbone

- Program management with action item & risk tracking, production planning, and stakeholder reporting.

- Manufacturing engineering for tooling, fixtures, assembly line design, and production readiness.

- Quality systems covering IQC, IPQC, OQC, sampling plans, and agency/safety compliance.

- Strategic sourcing with multi-country strategies, LLT planning, and secondary vendor qualification.

Frequently Asked Questions

Addressing the most common questions about our design services programs.

Let’s align your design with manufacturing realities.

Share your BOM, CAD, or requirements and we will prepare a DFM review plus a program playbook.

Start a project briefing

English

English  简体中文

简体中文